Innovation

Designed for Deconstruction: trees for easier pulping, papermaking

Breaking down wood is an energy intensive process. Researchers have now designed trees that fall apart, which could slash the cost of many industrial processes, including biofuel production.

Lignin is a naturally-occurring polymer commonly found in wood. Housed in the cell walls, it keeps plants upright, but it makes wood hard to break down for a number of industrial processes -- including biofuel production, pulping, and papermaking. Making lignin that’s easier to degrade means those huge, worldwide processes would generate less waste and require less energy, lower temperatures, and fewer chemicals.

Now, researchers say they’ve designed plant cell walls that fall apart, self-destructing under mild processing conditions. The work could slash the cost and energy needed to turn biomass into fuel.

To get rid of lignin, engineers typically heat biomass to 170 degrees Celsius (that’s over 500 degrees Fahrenheit) for several hours in the presence of alkaline compounds, Science reports. Its structure contains ether bonds that are difficult to degrade chemically; researchers have hoped to introduce weaker ester bonds into the lignin backbone. Previous work has suggested that the key may lie in the natural process of lignin assembly: from a pool of single molecules called monomers into a more complex polymer chain. The process could be engineered to incorporate new monomers that aren't native to lignin -- something new that could increase its degradability.

Enzymes called ferulates have been successful, but only in the lab. Now, a team led by John Ralph of the University of Wisconsin–Madison has successfully used ferulates in living plants for the first time, redesigning trees specifically for deconstruction.

- First, they found the gene that codes for the ferulate enzyme in Chinese Angelica (a root that’s used in traditional medicine).

- Then they put the gene into poplar trees and expressed it in tissue that forms lignin.

- Using structural analyses, they observed that poplar samples engineered in this way were able to produce the new monomers, export them to the cell wall, and ultimately incorporate them into the lignin backbone.

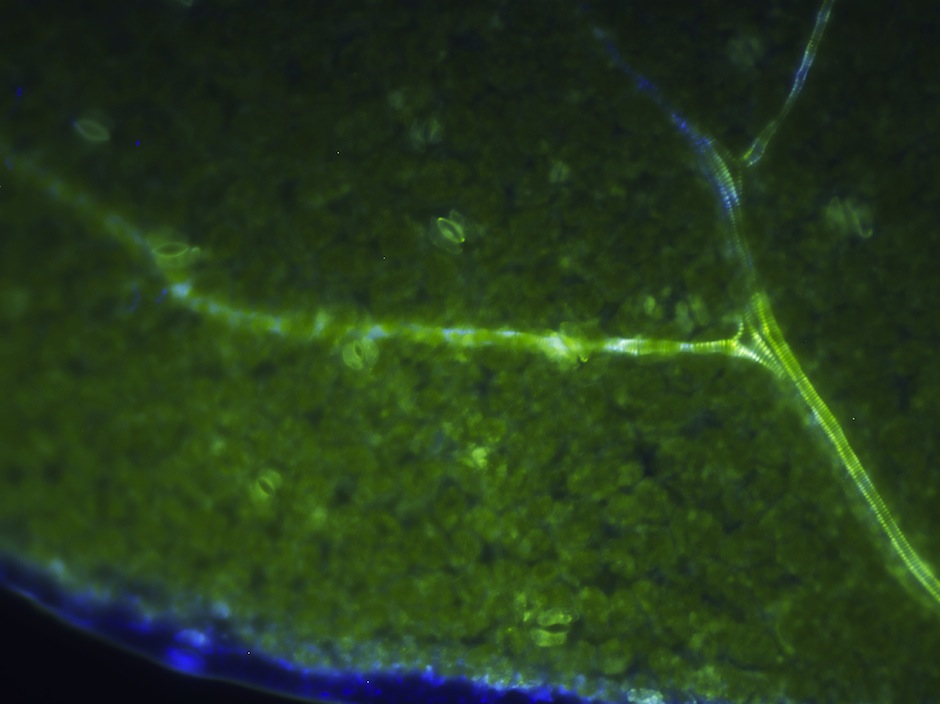

- The resulting poplars showed normal growth in greenhouses (pictured, right), but lignin from those plants showed improved digestibility.

- When ground up and subjected to 100 degrees Celsius (212 degrees Fahrenheit), the lignins just fell apart, releasing twice as many sugars as their wild-type kin do under the same conditions, Science reports.

Additionally, the genetically modified trees maintained their strength and growth. Previous attempts to alter genes resulted in stunted trees that were highly susceptible to wind, snow, pests, and pathogens. “Plants really need lignin,” Ralph explains.

Here, the plants produced a redesigned lignin that’s more easily “depolymerized,” providing less energy-demanding access to valuable plant products and “ultimately recovering more wood carbohydrate than is currently possible,” explains study coauthor Shawn Mansfield of the University of British Columbia. They call them “zip-lignins.”

“We rely on the same resource for everything from smartphones to gasoline. We need to diversify and take the pressure off of fossil fuels,” Mansfield says. “Trees and plants have enormous potential to contribute carbon to our society.”

The work was published in Science last week.

Images: Shawn Mansfield, UBC

This post was originally published on Smartplanet.com