IBM breakthrough means its a nanoscale world after all

It's a nanoscale 3D world after all. IBM researchers have produced a breakthrough technique that allows scientists to create nanoscale objects. The first mission was to produce the smallest 3D map of the world ever.

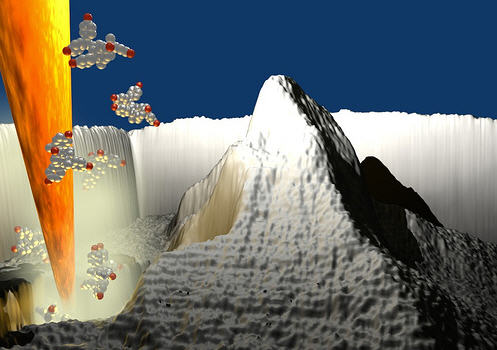

Here's a look at a 3D image of the heated nanoscale silicon tip carving out a replica of the Matterhorn, the Swiss mountain. The 25 nanometer-high 3D replica of the Matterhorn was created on molecular glass.

The map was created using "nanopatterning" with a silicon tip (right) that chisels away material from a substrate. This nanoscale tip is 10,000 times smaller than an ant, or 500 nanometers in length and a few nanometers high. IBM said that said the tip can create 2D and 3D patterns and structures as small as 20 nanometers.

Gallery: IBM's 3D nanoscale breakthrough makes the world a lot smaller

The paper outlining the discovery is published in the journals Science and Advanced Materials. In the paper, IBM's research team, based in San Jose and Zurich, walk through how it created a complete 3D map 22 by 11 micrometers. How small is that? Think 1,000 world maps on a grain of salt. The 3D map is composed of 500,000 nanoscale pixels and took 2 minutes and 23 minutes to create.

Here's a look at the 3D map:

What does this breakthrough mean? IBM said that its tool can be used to create tiny machines that can repair health issues. In addition, IBM's breakthrough could affect everything from electronics manufacturing to semiconductors to medicine and life sciences to opto-electronics. Of course, nanopatterning can benefit IBM's chip and systems business in the future and applications for water purification and medical diagnostics.

A IBM spokeswoman said that IBM is in talks to license the technology to other companies and universities.

An snippet from the Science article explains the significance:

For patterning organic resists, optical and electron-beam lithography (EBL) are the most established methods, but at resolutions below 30 nanometers, inherent problems exist caused by unwanted exposure of the resist in nearby areas. We present a scanning-probe lithography method based on the local desorption of a glassy organic resist by a heatable probe. We demonstrate patterning at a half pitch down to 15 nanometers without proximity corrections and throughputs approaching those of Gaussian EBL at similar resolution. Patterns can be transferred to other substrates, and material can be removed in successive steps in order to fabricate complex three-dimensional structures.