The robots that conquered Fremont: Watch 'em making Teslas

--

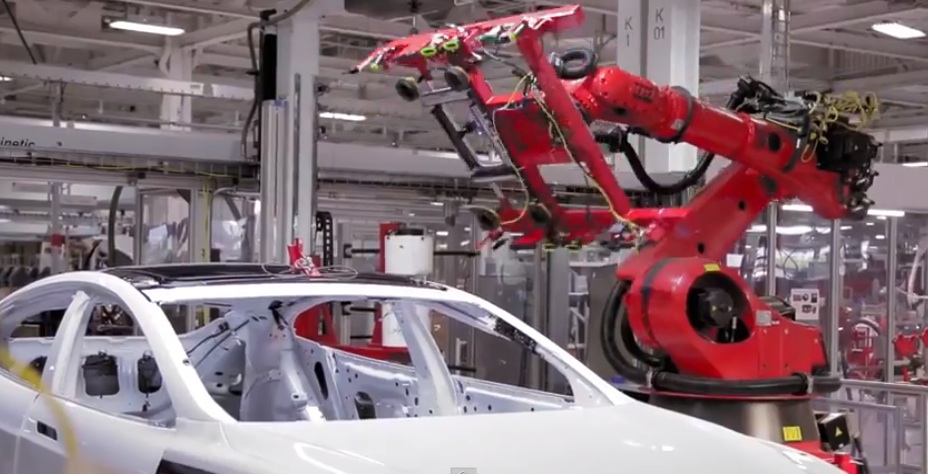

It's amazing what 160 robots can do. Get 'em together with 20,000 pounds of aluminum coils, and the next thing you know, you have a car.

That's what happens at the Tesla factory in Fremont, California, where robots ranging in size "from teeny little ones to huge ones" can unroll sheets of metal, stamp them, and paint them into electrically-powered Tesla S sedans within three to five days, according to Gilbert Passin. He's Tesla's vice president of manufacturing who appears in a lively video that Wired magazine posted from inside the plant, on YouTube.

To help you believe, watch it below. You'll marvel as robots (the huge ones) chuck around cars as if they were chiclets. Some are even so versatile they do seats as well as windows!

Get excited as you watch the "marriage" of underbodies with front ends, brought to you by Tesla body center manager Eric Purcell. You'll ogle over the "five different joining methods," all there on graphic display: adhesive; self piercing rivets; cold level transfer; conventional resistance welding; and yes, yes, yes, the new Delta Spot welding system!

It's the pinnacle of automation full of lasers and half-built cars that guide themselves around on magnetic strips. It includes 3,000 humans too. Apparently backwards baseball hats maximize their productivity.

Whatever it takes! See for yourself:

Video from Wired via YouTube. Photo is a screen grab from the video.

More Teslas on SmartPlanet:

- Tesla added to NASDAQ 100

- Watch Tesla’s 90-second electric vehicle battery swap demonstration

- Tesla recalls Model S vehicles over safety concerns

- Tesla plans to triple Supercharger network

- Tesla pays off $465 million loan nine years early

- Tesla Model S is top-scoring car: Consumer Reports

- Tesla rolls out loaner, valet service

- Tesla Model S races past sales targets

- Tesla to Boeing: We can get your Dreamliner up again

This post was originally published on Smartplanet.com